The United States has long been a leading manufacturer of goods, but it has become increasingly difficult to compete with other countries that have lower production costs in recent years. For example, countries like China have much lower production costs when compared to the United States, making it more affordable and more efficient to manufacture items there. As a result, many American companies are now moving their manufacturing facilities back inside the country in response to this challenge.

There are several reasons for this shift. First, labor costs in other countries have risen, making it more expensive to produce goods overseas. Additionally, the quality of American-made products is generally higher than products made in other countries. Finally, companies can better control their supply chains and reduce shipping costs by manufacturing goods domestically.

The return of manufacturing jobs to the United States is good news for American workers. These jobs tend to be well-paid and offer good benefits. They also tend to be located in areas that have been economically depressed, providing a much-needed boost to these communities. However, manufacturing still needs to be profitable and efficient, even inside the country. Here are ways technology is dealing with that.

Advanced Manufacturing Techniques

Technology is improving manufacturing in the United States by making it more efficient. New manufacturing techniques, such as 3D printing, allow companies to produce goods faster and with less waste. Additionally, these techniques often require fewer workers, which can help reduce labor costs. Speaking of 3d printing, here’s how it’s affecting the industry in the United States.

3d Printing

3D printing is a type of additive manufacturing. It is the process of solid objects from software design. The creation of a 3D printed object is achieved using an additive process, making it a lot more efficient. 3D printing differs from traditional subtractive manufacturing, which involves cutting away materials to create an object.

3D printing has been around since the 1980s, but it was only recently that the technology became cheap enough and widespread enough to be used in manufacturing. 3D printers can now be found in many homes and businesses, and they are becoming increasingly affordable.

There are many advantages to 3D printing. First, it is an additive process, so there is little waste. Second, 3D printing can be done quickly. Third, it is possible to create complex objects with 3D printing that would be difficult or impossible to create using traditional manufacturing methods.

3D printing is already being used in many different industries. For example, 3D printed prosthetics and implants are becoming increasingly common in the medical field. In the automotive industry, 3D printed parts are used to create prototype vehicles. 3D printed parts are being used to build rockets and satellites in the aerospace industry. And in the consumer goods industry, 3D printed products are being used to create everything from eyeglass frames to shoes.

Another great improvement in the country’s manufacturing industry is pneumatic systems.

Better Pneumatic Systems

Pneumatic systems are powered by compressed air. They are often used to operate tools and machinery. Pneumatic systems are more efficient than hydraulic systems, which are powered by oil. They are also more environmentally friendly because they do not use fossil fuels. Air control valves are essential for these pneumatic systems to work. They have improved throughout the years, making these systems a lot safer to use.

Pneumatic systems have been around for centuries, but they were not widely used in manufacturing until the late 19th century. Since then, pneumatic systems have become increasingly common in factories. Today, most large factories have some form of pneumatic system.

Pneumatic systems have many advantages over other types of power sources. First, they are much cheaper to operate than hydraulic or electric systems. Second, they are much easier to maintain. Third, they are much more efficient. Fourth, they are much cleaner and quieter than other types of power sources. Fifth, they are much safer to use.

Pneumatic systems have a few disadvantages as well. They require a constant, they can be dangerous if not used properly, and lastly, they can be hard to control.

Better Quality Control

Quality control is another area where technology is having a positive impact on manufacturing. In the past, quality control was often a manual process that was prone to human error. Today, however, there are many automated quality control procedures that can ensure that products meet high standards. These procedures can also identify defects more quickly, which can save time and money.

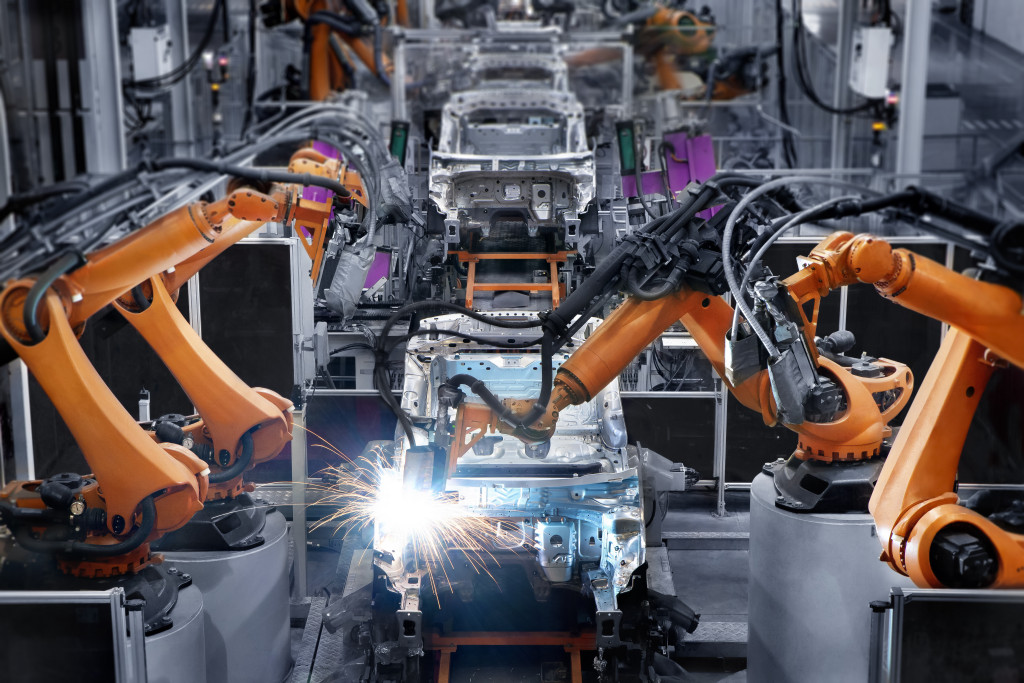

Increased Automation

Another way technology is changing manufacturing is by increasing automation. In the past, most manufacturing jobs were done by human workers. Today, however, many of these jobs are being done by machines. This trend is expected to continue as technology advances.

There are many advantages to increased automation. It can improve quality control because machines are more accurate than humans. Automation can increase production speed because machines can work faster than humans. It reduces labor costs because machines do not need to be paid a salary. Lastly, it can improve safety because there are fewer opportunities for human error.

As you can see, technology is changing the manufacturing industry in many different ways. These changes are making factories more efficient, more productive, and safer. We can expect these trends to continue as technology advances.